For Cerescon, MTA has managed to improve the price-performance ratio of the core module in the asparagus harvester by a factor of three. The number of harvested asparagus per hour has improved by 100% and the price has decreased by 40%. That is the result of effective co-creation at the very front of the process.

Being able to cooperate from white paper ensures that MTA can create an optimal integrated design in which both functional product and production design go hand in hand. This results in a shorter lead time and lower product costs in series.

V2 model

With every functional step, we immediately check whether it is easy to make in series and for the best cost price. That way of multidisciplinary design, in which product and production architecture are integrally designed, is the core of our approach. We call it the V2 model. We also applied this in the redesign of the core module in the selective asparagus harvester. By bringing together the knowledge and experience of Cerescon and that of MTA, we have come to the right considerations from a machine, process, specification and cost perspective. This has resulted in a solution whose price-performance ratio is a factor of three better, or significantly lower harvest costs per asparagus.

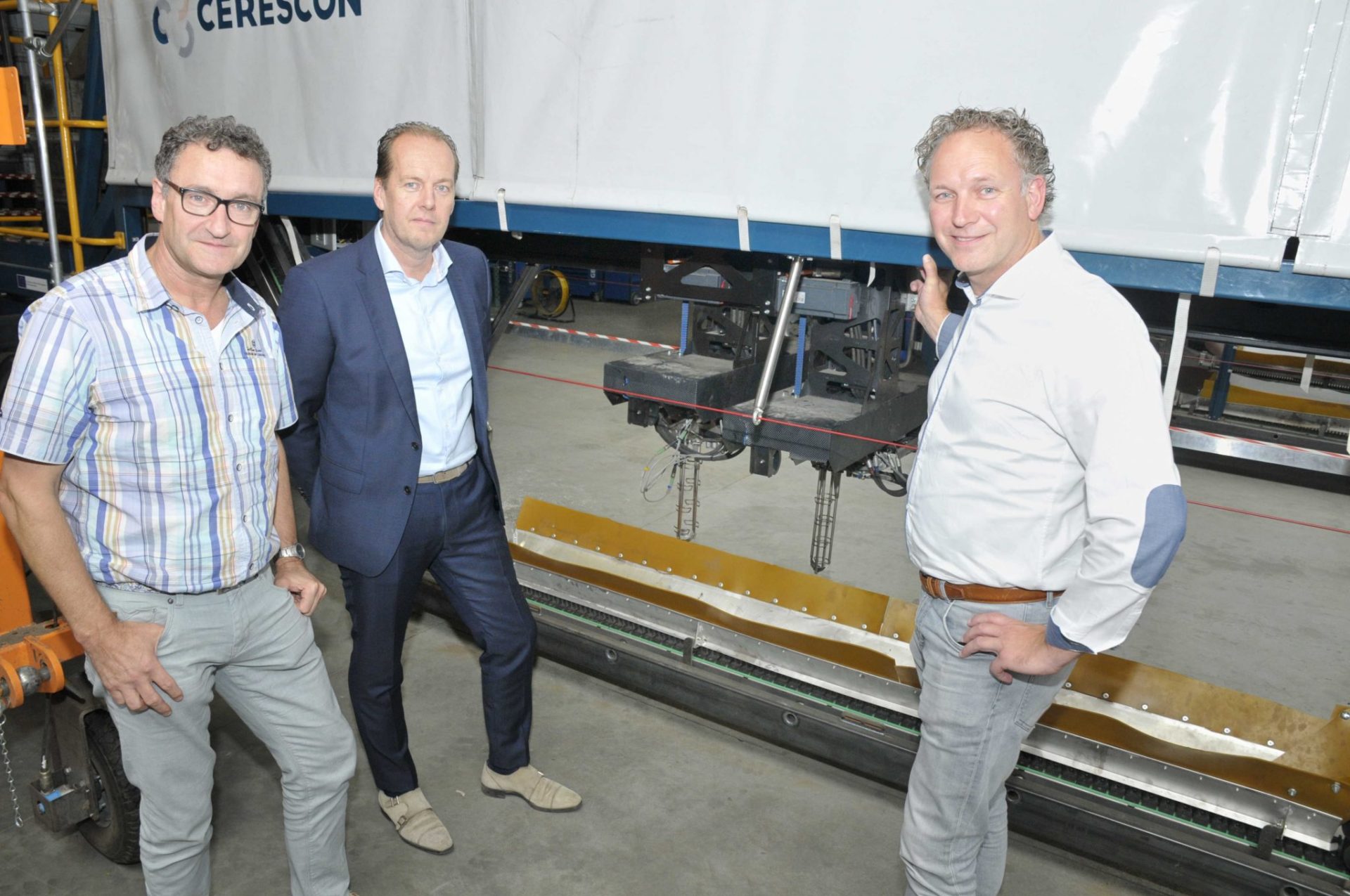

Link Magazine interviewed Cerescon and MTA about this co-creation. Read the full interview.

Photo source: Link Magazine